Kwinkqubo yokwenziwa komngundo, inxalenye yokubumba i-mold isoloko ifuna ukucocwa phezulu.Ukuqonda itekhnoloji yokupolisha kunokuphucula umgangatho kunye nobomi benkonzo yokubumba kwaye ngaloo ndlela kuphuculwe umgangatho wemveliso.Eli nqaku liza kwazisa umgaqo wokusebenza kunye nenkqubo yokupholisa i-mold.

1. Indlela yokupholisa umngundo kunye nomgaqo wokusebenza

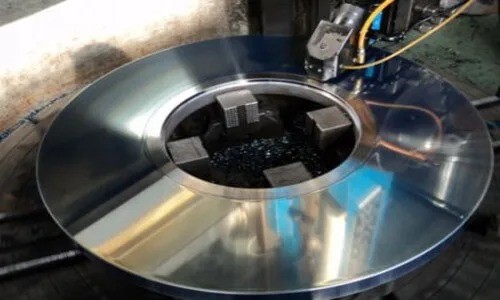

Ukugulisa umngundo ngokuqhelekileyo kusebenzisa imicu yamatye e-oyile, amavili oboya, i-sandpaper, njl. njl., ukwenzela ukuba umphezulu wezinto eziphathekayo ukhubazeke ngokweplastiki kwaye inxalenye ye-convex yomphezulu we-workpiece isusiwe ukufumana indawo egudileyo, eyenziwa ngesandla. .Indlela yokugaya i-super-fine and polishing iyafuneka kumgangatho ophezulu.I-super-fine grinding and polishing yenziwe ngesixhobo esikhethekileyo sokugaya.Kwi-polish liquid equkethe i-abrasive, icinezelwe ngokubhekiselele kumphezulu owenziwe ngomatshini ukwenza i-high-speed rotary motion.Ukugudisa kunokufikelela kuburhabaxa bomphezulu beRa0.008μm.

2. Inkqubo yokupolisha

(1) ipolishi erhabaxa

I-Fine Machining, i-EDM, ukugaya, njl.Kuphinde kubekho ukugaywa kwelitye le-oyile ngesandla, umcu welitye le-oyile kunye ne-kerosene njengesithambiso okanye into yokupholisa.Umyalelo wokusetyenziswa ngu 180#→240#→320#→400#→600#→800#→1 000#.

(2) Ukugulisa kancinci

I-semi-finishing ikakhulu isebenzisa i-sandpaper kunye ne-kerosene.Inani le-sandpaper lilandelelana:

400#→600#→800#→1000#→1200#→1500#.Enyanisweni, i-#1500 sandpaper isebenzisa kuphela isinyithi sokubumba esilungele ukuqina (ngaphezulu kwe-52HRC), kwaye ayifanelekanga kwintsimbi eqiniweyo ngaphambili, kuba inokubangela umonakalo kumphezulu wentsimbi yangaphambili kwaye ayikwazi ukufezekisa umphumo ofunekayo wokupolisha.

(3) Ukugulisa kakuhle

Ukugulisa okucokisekileyo kusebenzisa intlama yedayimane ebrasive.Ukuba ukusila ngevili lelaphu lokukhazimlisa ukuxuba idayimani engumgubo orhabaxa okanye intlama erhawukileyo, ulandelelwano lwesiqhelo lokusila yi-9 μm (1 800 #) → 6 μm (3 000 #) → 3 μm (8 000 #).I-9 μm yedayimani intlama kunye nevili lelaphu lokupholisha lingasetyenziselwa ukususa iimpawu zeenwele kwi-1 200 # kunye ne-1 50 0 # sandpaper.Ukukhazimliswa ke kuqhutywa ngentsimbi evakalelwayo kunye nedayimani ngokomyalelo we-1 μm (14 000 #) → 1/2 μm (60 000 #) → 1/4 μm (100 000 #).

(4) Indawo yokusebenza ephucukileyo

Inkqubo yokupholisa kufuneka iqhutywe ngokwahlukileyo kwiindawo ezimbini zokusebenza, oko kukuthi, indawo yokucoca ngokucokisekileyo kunye nendawo yokucoca ecolekileyo iyahlukana, kwaye kufuneka kuthathelwe ingqalelo ukucoca amasuntswana esanti aseleyo phezu kwendawo yokusebenza ngaphambili. inkqubo.

Ngokubanzi, emva kokucocwa ngokurhabaxa ngelitye le-oyile ukuya kwi-1200 # sandpaper, i-workpiece kufuneka icocwe ukuze icoceke ngaphandle kothuli, iqinisekise ukuba akukho masuntswana othuli emoyeni abambelela kumphezulu wokungunda.Iimfuno zokuchaneka ngaphezu kwe-1 μm (kubandakanywa ne-1 μm) zingenziwa kwigumbi lokuhlambela elicocekileyo.Ukupholisha okuchane ngakumbi, kufuneka kube kwindawo ecocekileyo, njengoko uthuli, umsi, inkwethu kunye namathontsi amanzi anokukrazula indawo ekhazimlisiweyo ephezulu.

Emva kokuba inkqubo yokupolisha igqityiwe, umphezulu we-workpiece kufuneka ukhuselwe eluthulini.Xa inkqubo yokupolisha iyekile, zonke ii-abrasives kunye ne-lubricants kufuneka zisuswe ngononophelo ukuze kuqinisekiswe ukuba umphezulu we-workpiece ucocekile, kwaye emva koko umaleko we-mold anti-rust coating kufuneka utshizwe phezu kwendawo yokusebenza.

Ixesha lokuposa: Jan-10-2021